HOME > Product > LEVEL PARKING SYSTEM

HOME > Product > LEVEL PARKING SYSTEM

Product

LEVEL PARKING SYSTEM

The level parking system is commonly used for medium to large buildings due to its superior space efficiency. It is designed to supplement multi-level parking spaces with vertical and horizontal directions to facilitate the entry and exit of cars. The pallet loaded with the car moves up and down using the vertical circulation rail of the lift. It can also move laterally by pitch-shifting. It can be installed in various ways considering site conditions. The different models and types are classified as follows

According To The Entry Location

According To The Turntable Installation

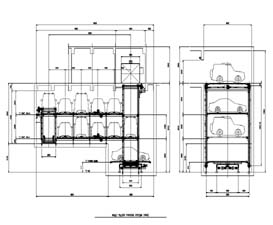

- ALUUT Type: The built-in turntable is installed at the top entry module of the ALU type.

- ALULT Type: The built-in turntable is installed at the bottom of the lift of the ALU type. This type is appropriate when the permissible change in direction at the entry module is limited.

- ALUMT Type: The built-in turntable is installed on the ALUM type.

- Lift : The main lift and sub lift that are located both at the left and right end of the system enable the system to simultaneously move the pallet in vertical and horizontal direction in order to maneuver the car.

- Side sliding : The side sliding located at the center of the system enables the system to simultaneously move the upper and lower pallets laterally in order to maneuver the car.

- Pallet : The pallet is the plate that supports the car. It is designed to enable the linked movement between pallets, which consist of lug type connections. When pallet is moved horizontally, the pallets are disconnected to enable up and down horizontal movement of the car.

- Our parking system is designed based on the cars shown in the above allowable car specifications. The system for other cars can also be provided as an option.

Functions

System Specification

System control |

Operation |

Touch screen |

|||

Motor control |

Invertor control |

||||

Safety device |

Entry module lead-in lamp and interior guide lamp, guide mirror |

||||

Entry module car position sensor |

|||||

Fall protection fence |

|||||

Overrun protection system |

|||||

Emergency stop system |

|||||

Chain breakage detector |

|||||

Monitoring system for safe operation |

|||||

Vertical moving |

Motor |

11kw ~ 18.5kw DC Brake |

|||

Speed |

20 ~ 25 M/min |

||||

Horizontal moving |

Motor |

3.7kw ~ 5.5kw DC Brake |

|||

Speed |

20M/min |

||||

Turntable |

Motor |

1.5 ~ 3.7 kw x 4p |

Speed |

2.5 r.p.m /min |

|

Electric source |

AC 3ик 415V 50Hz |

||||

Features

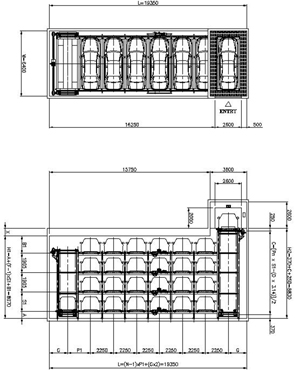

This is the most basic system that features the external turntable function. The entry module is installed either at the left or at the right of the system. The height of the entry module can be adjusted by changing the number of vertical circulation rails of the main lift. The provision of a pit for the lift may be necessary, depending on the site conditions.

In this case, however, the construction cost can be reduced due to the split-level design of the system, which maximizes the space between bottom level of the parking room and the bottom level of the lift.

The lift pit is not shown in this figure since the pit height varies according to the site conditions.

Legend

Mark |

Explanation |

Mark |

Explanation |

H1 |

Minimum height for parking |

H2 |

Minimum height for entry module |

N |

Number of pallet rows |

A |

Height measured from the bottom end of the pallet to the floor level ( 655mm ) |

P1 |

Pallet row pitch ( 2250mm ) |

B1 |

Height measured from bottom end of the ceiling to the bottom end of the pallet |

P2 |

Pallet row pitch ( 2400mm ) |

B2 |

Height measured from the bottom end of ceiling to bottom end of pallet Car (L) size = 2173mm |

G |

Internal distance of the wall from lift center ( 1800mm ) |

C |

Distance between lift axles |

F |

Level |

Pn |

Number of turn rails |

S1 |

1 section chain pitch (RS120 x 50Link = 1905mm ) |

D |

Driving axle Sprocket P.C.D ( ик 231.48 ) |

S2 |

1 section chain pitch ( RS120 x 60Link = 2286mm ) |

X |

Ceiling Slab thickness |

L |

Internal length |

W |

Internal width |

Dimensions

Rows |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

||||||||||||||

Capacity |

2nd level |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

|||||||||||||

3rd level |

14 |

17 |

20 |

23 |

26 |

29 |

32 |

35 |

||||||||||||||

4th level |

18 |

22 |

26 |

30 |

34 |

38 |

42 |

46 |

||||||||||||||

Internal distance |

L |

14,850 |

17,100 |

19,350 |

21,600 |

23,850 |

26,100 |

28,350 |

30,600 |

|||||||||||||

Parking Height |

Layer |

2 |

3 |

4 |

5 |

6 |

Car size |

|||||||||||||||

H1 |

4,260 |

6,165 |

8,070 |

9,975 |

11,880 |

M1 |

||||||||||||||||

5,120 |

7,400 |

9,690 |

11,970 |

14,260 |

L |

|||||||||||||||||

Entry module height |

Number of Rails |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

Car size |

|||||||||||||

H2 |

5,020 |

5,980 |

6,925 |

7,880 |

8,830 |

9,785 |

10,735 |

M1 |

||||||||||||||

5,970 |

7,115 |

8,260 |

9,400 |

10,545 |

11,685 |

12,830 |

L |

|||||||||||||||

Level Parking System - Download PDF File

- DRS Korea , Suite 502 Dorim Doosan Bears Tower Guro Seoul Korea, Factory Kuynggi-do Kumpo-si,

Mr. S. H. Cang | Tel : +821072971987 | Email : info@drsenc.com | shcang@drsenc.com Copyright(c) DRS E&C AUTOMATED PARKING SYSTEM. All right Reserved.